Wearable technology is changing logistics. It makes work faster, safer, and better. Companies use new devices like AR wearables, hands-free scanners, and smart glasses. These tools help workers move and track goods.

Metric | Improvement |

|---|---|

Fewer workplace accidents | 15% |

More work done during busy times | 15-20% |

Fewer mistakes in careful tasks | 35-40% |

Fewer workplace injuries | 25-30% |

Tasks done better with exoskeletons | 25% |

Fewer muscle and bone injuries | 40% |

DHL got 25% more work done after using smart glasses in its warehouses. UPS used wearable scanners to track packages and deliver them better. This gave them a 3.5% boost in work done. These real examples show that new tools can lower mistakes and keep workers safe.

Key Takeaways

Wearable technology helps logistics workers do their jobs faster and safer. It also helps them make fewer mistakes. Workers use devices like smart glasses, scanners, and voice headsets.

These devices help with order picking and inventory management. They also help with safety and communication. This leads to higher productivity and fewer injuries in warehouses.

Wearables give real-time data to managers. This helps managers make quick decisions. It also helps them improve training.

Wearables help keep workers healthier and safer at work. There are some challenges like high costs and system integration.

Worker acceptance and privacy concerns are also problems. But these can be managed with good planning and training.

In the future, trends like augmented reality will help even more. AI-powered wearables will make logistics work smarter, faster, and safer. This will help companies stay competitive.

Wearable Technology in the Logistics Industry

Device Types

Wearable technology is used in logistics with many smart devices. These tools help workers finish jobs faster and make fewer mistakes. Some common device types are:

Smart Glasses

These glasses use augmented reality. They show picking steps and item spots right in front of the worker’s eyes. Workers can scan barcodes and finish tasks without using their hands.

Wearable Scanners

These are worn on the finger, wrist, or glove. Workers scan barcodes and RFID tags fast. This hands-free barcode scanning makes order picking and checking inventory quicker.

Wearable computers and voice headsets

Workers get spoken instructions and give voice commands. These devices work with robots and dispatchers for better teamwork.

Rugged Wearables

These are arm computers and tablets that do not break easily. They can handle drops, dust, and water. They help with picking, receiving, and shipping in tough places. Enable hands-free barcode scanning.

Note: The COVID-19 pandemic made companies use wearable technology faster. These devices help keep workers safe and keep work going when there are not enough workers.

Key Features

Wearable technology is special in logistics because of its smart features. These features make work easier and safer for workers:

Real-time data access: Workers see inventory, picking steps, and shipping details right away. This helps stop mistakes and saves time.

Hands-free operation: Devices like smart glasses and voice headsets let workers use both hands. This makes them faster and helps stop things from dropping.

Seamless integration with warehouse management systems (WMS): Wearables connect to WMS without wires. They update inventory and job status right away. Managers get good data to make better choices.

Safety and health monitoring: Some wearables check heart rate, tiredness, and movement. They warn workers and managers about unsafe actions. This helps stop injuries.

Ergonomic design: These devices are light and comfy. They help workers feel less tired and work longer.

Easy training: Simple screens help new workers learn fast and start working sooner.

Wearable technology transforming the way warehouses operate, changes logistics by linking workers, devices, and systems. Companies like DHL and Amazon say they get more work done and make fewer mistakes with these tools.

Applications

Order Picking

Order picking is a very important job in logistics. Companies use smart glasses and AR devices to help workers in warehouses. These tools show workers where to go and what to pick. Workers do not need to look at paper lists or screens. This helps them move faster and make fewer mistakes.

AR-guided picking gives workers pictures and better paths. This saves time and helps them pick orders faster.

Smart glasses show where items are and how many to get. Workers can pick items with both hands and work quickly.

Workers scan barcodes and check items right away. This helps them pick the right things and the right amount.

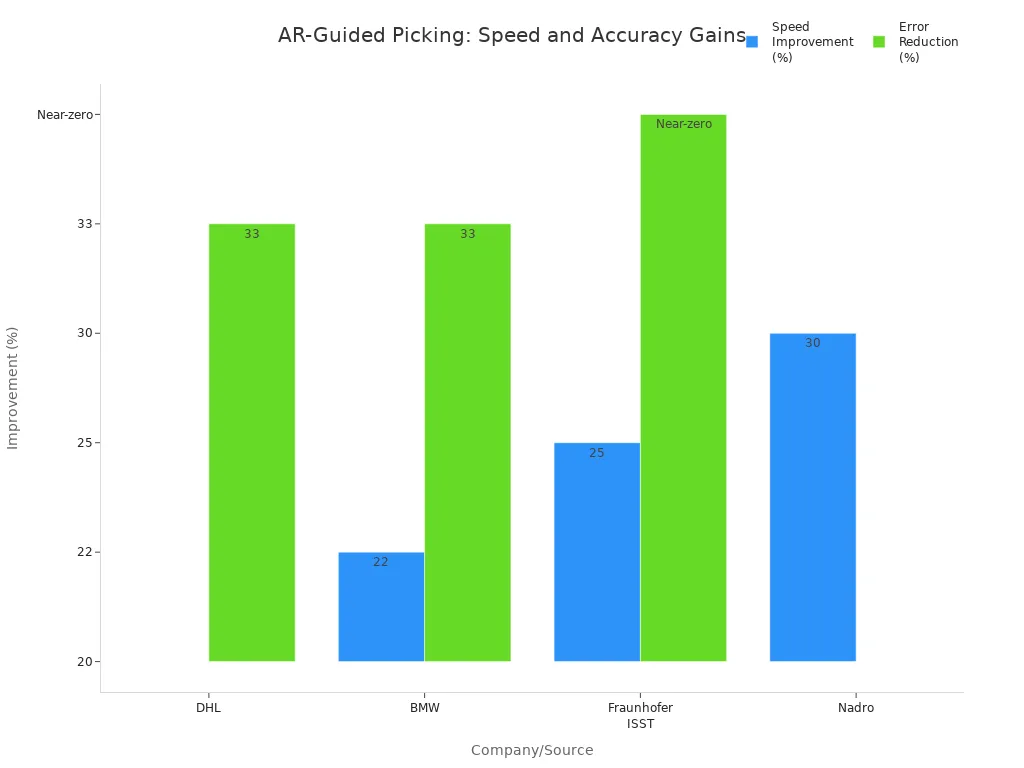

DHL used AR smart glasses and picked 25% more orders. BMW saved 22% of time and made 33% fewer mistakes with this technology.

Company/Source | Improvement in Speed | Improvement in Accuracy/Error Reduction | Additional Benefits | Challenges |

|---|---|---|---|---|

DHL (Simon Woodward) | 15-25% more picks/hour | Up to 33% fewer errors | Hands-free picking, better training, user-friendly | Initial cost, tech maturity |

BMW (Nela Murauer) | 22% time saving | 33% fewer errors | Employee satisfaction, pilot use of smart glasses and employee safety | Hardware comfort, battery life |

Fraunhofer ISST (Jan Cirullies) | 15-35% faster processes | Near-zero picking errors | High satisfaction, ergonomic benefits, flexible deployment | Device weight, battery life |

Nadro (Pharma wholesaler) | 30% less picking time | N/A | SAP integration, TeamViewer Frontline | N/A |

Inventory

Inventory management is easier and more correct with wearables. Workers use wearable barcode scanners, RFID-based wearables, and smartwatches to check stock. These devices connect to warehouse systems and update inventory right away.

Wearable Technology Type | Main Application in Logistics | Industry Challenges Addressed |

|---|---|---|

RFID-Based Wearables | Inventory tracking and management | Speeds up and improves accuracy of inventory management; reduces manual data entry delays |

Smartwatches | Real-time task updates, communication, health monitoring | Enables hands-free communication; monitors worker strain to enhance safety; improves task management |

Workers scan items fast and do not need to stop for handheld devices. This cuts down on typing and makes stock checks quicker. Picavi uses smart glasses and finger scanners in food warehouses. They save 8% to 12% more time than with old scanning tools.

Safety

Safety is always very important in logistics. Wearable devices help keep workers safe by watching their moves and health. Exoskeletons help with heavy lifting and protect muscles and joints. IoT sensors and smartwatches check heart rate, body heat, and how workers move.

Devices warn workers if they lift, twist, or bend in unsafe ways. They beep or vibrate to help stop injuries.

Supervisors use data from wearables to teach workers and change warehouse layouts for better safety.

Wearables watch vital signs and send alerts if workers get too hot or tired. This helps stop heat stress and overwork.

Companies use this data to plan work and break times for each worker. This keeps everyone safer and healthier.

Note: Using wearable technology for a long time helps workers build safer habits and lowers injuries.

Communication

Good communication helps logistics teams work well together. Wearable devices like smartwatches and voice headsets let workers talk and get updates right away. Workers can stay in touch with managers and teammates without stopping their jobs.

Managers give tasks to drivers and workers in real time. This stops delays and cuts down on mistakes.

Hands-free devices let workers do their jobs while talking to others.

Wearables link to systems that track team work and how resources are used.

Devices help teams talk even if they are far apart or in big warehouses.

Safety features like emergency buttons and alerts help protect workers and get help fast.

A study showed companies using wearables had 20% more worker productivity and 30% faster team communication. One company used fitness trackers and had 25% fewer miscommunications. This shows that sharing data right away helps teams work better.

Benefits

Worker Efficiency

Wearable technology helps logistics companies work better and faster. Workers use hands-free devices to scan items quickly. They follow instructions without stopping their work. This makes picking and packing go faster. Augmented reality glasses show where products are. This saves time and stops confusion. Wearables send real-time data to warehouse systems. Managers use this data to make fast choices. DHL used smart glasses and AR tools. They picked 25% more orders after using them.

Hands-free scanning helps workers move faster.

AR guidance saves time and stops confusion.

Real-time updates help managers plan quickly.

Accuracy

Order accuracy gets better with wearable devices. The Wyoming Liquor Division used voice wearables. They kept a 99.9% order accuracy rate. They also worked 15% faster. Voice and scanning tools help workers pick the right items. These tools help stop mistakes. Smartwatches and visual cues help check orders before shipping.

Companies using wearable technology make fewer mistakes and have happier customers.

Safety

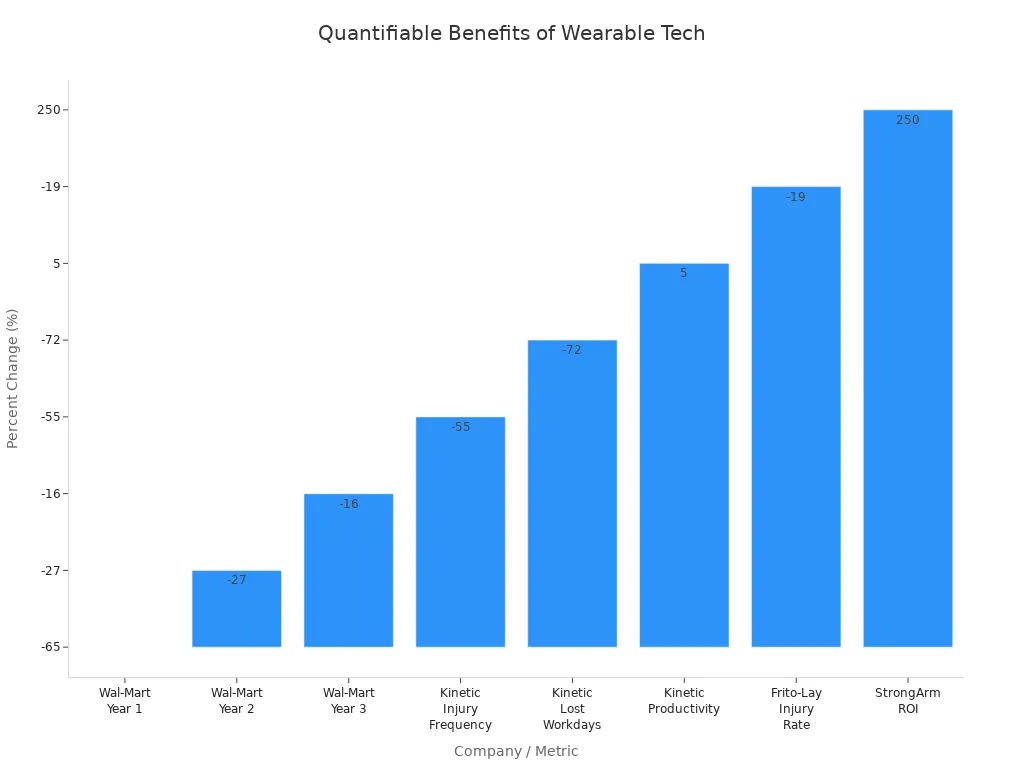

Safety improves with wearable devices. Companies watch worker health and movement to stop injuries. One logistics company had 30% fewer tiredness problems after using wearables. Workers were also happier. The table below shows how Wal-Mart and Frito-Lay lowered injuries and lost workdays:

Company / Client | Metric | Quantifiable Benefit |

|---|---|---|

Wal-Mart (StrongArm) | Ergonomic-related injuries | 65% less in year 1; 27% less in year 2; 16% less in year 3 |

Kinetic (Frito-Lay) | Injury frequency | 50% to 60% lower |

Kinetic | Lost workdays | 72% less |

Kinetic | Boost Productivity | 5% higher |

Frito-Lay (Kinetic) | Injury rate | 19% less at nine sites in two quarters |

Lineage Logistics | OSHA recordable incidents | Big drops after pilot program |

StrongArm Technologies | Return on Investment (ROI) | 250% ROI from fewer injuries and lower rates |

Data Insights

Wearable devices collect real-time data on workers and tasks. This helps managers find problems early and keep workers safe. Wearables connect with warehouse and business systems. Leaders get better information to make choices. Companies use this data to train workers and plan work. Teams stay connected and work better. This leads to more work done, fewer mistakes, and safer jobs.

Real-time checks help managers act fast.

Data from wearables helps make training and safety better.

Connecting with business systems helps leaders make smart choices.

Challenges

Costs

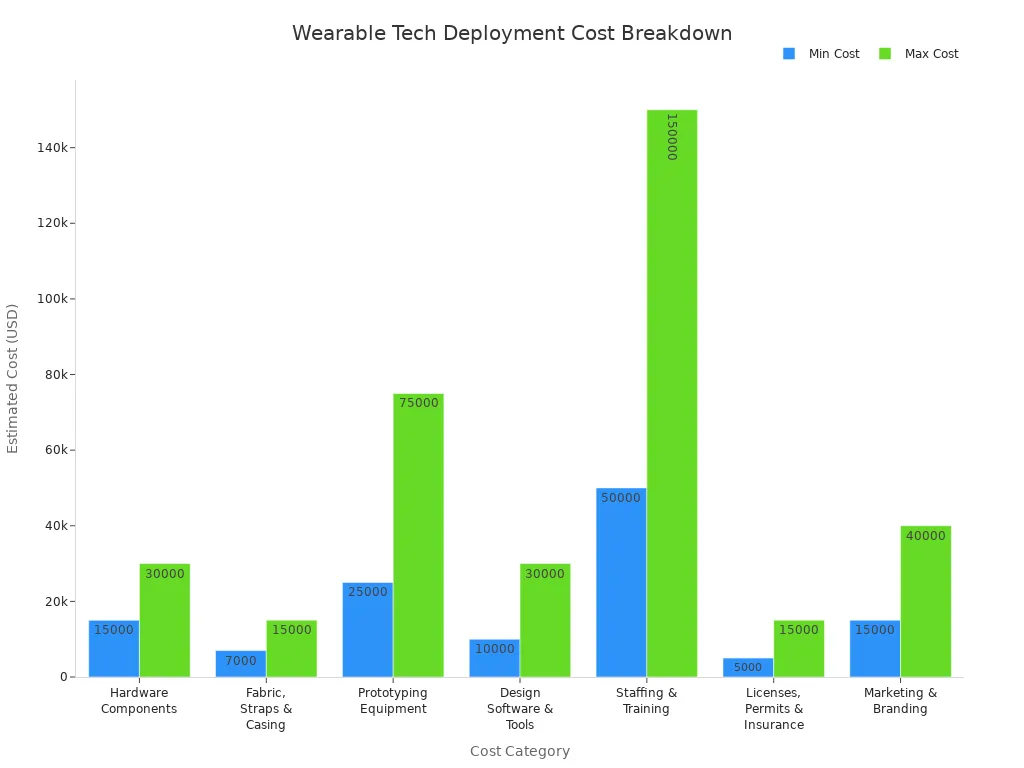

Using wearable technology in logistics costs a lot of money. Companies need to pay for devices, software, and training. The table below shows how much each part can cost:

Cost Category | Estimated Cost Range | Description / Notes |

|---|---|---|

Hardware Components | $15,000 – $30,000 | Electronic parts and sensors for device performance. |

Fabric, Straps & Casing | $7,000 – $15,000 | Materials for durability and comfort. |

Prototyping Equipment | $25,000 – $75,000 | Tools for testing and building new devices. |

Design Software & Tools | $10,000 – $30,000 | CAD and graphic design tools, including licenses. |

Staffing & Training | $50,000 – $150,000 | Salaries and training for staff and engineers. |

Licenses, Permits & Insurance | $5,000 – $15,000 | Legal and compliance costs. |

Marketing & Branding | $15,000 – $40,000 | Building brand presence and awareness. |

Starting costs can be between $155,000 and $420,000. These high prices can make it hard for small companies to use wearables.

Integration

Connecting wearable devices to old warehouse systems is hard. Many companies use old software that does not work well with new devices. Teams need to update systems so data moves smoothly. This often means more IT help and careful planning. Companies also have to follow rules, pay extra taxes, and obey local laws. These things can make it cost more and take longer to start using wearables.

Adoption

Some workers do not want to use wearable technology. They worry about the price, comfort, and safety. Some are not sure how their data will be used. Others do not trust new devices or do not see the benefits. Companies help by letting workers help choose devices and by making them comfortable. Good training also helps. How workers feel about technology is important. When companies explain the good parts and answer questions, workers are more willing to try wearables.

Tip: Letting workers try devices early and giving hands-on lessons helps them accept new technology.

Privacy

Wearable devices collect private data like where workers are and their health. This makes some workers worry about privacy. They want to know who sees their data and how it is used. Laws like GDPR, HIPAA, and CCPA say companies must protect this data and get clear permission. If companies break these rules, they can get big fines and lose trust. The best way is to use strong data protection, clear rules, and let workers control their own data. Companies need to keep workers’ privacy safe while still getting the benefits of wearables.

Future Trends

AR and Immersive Tech

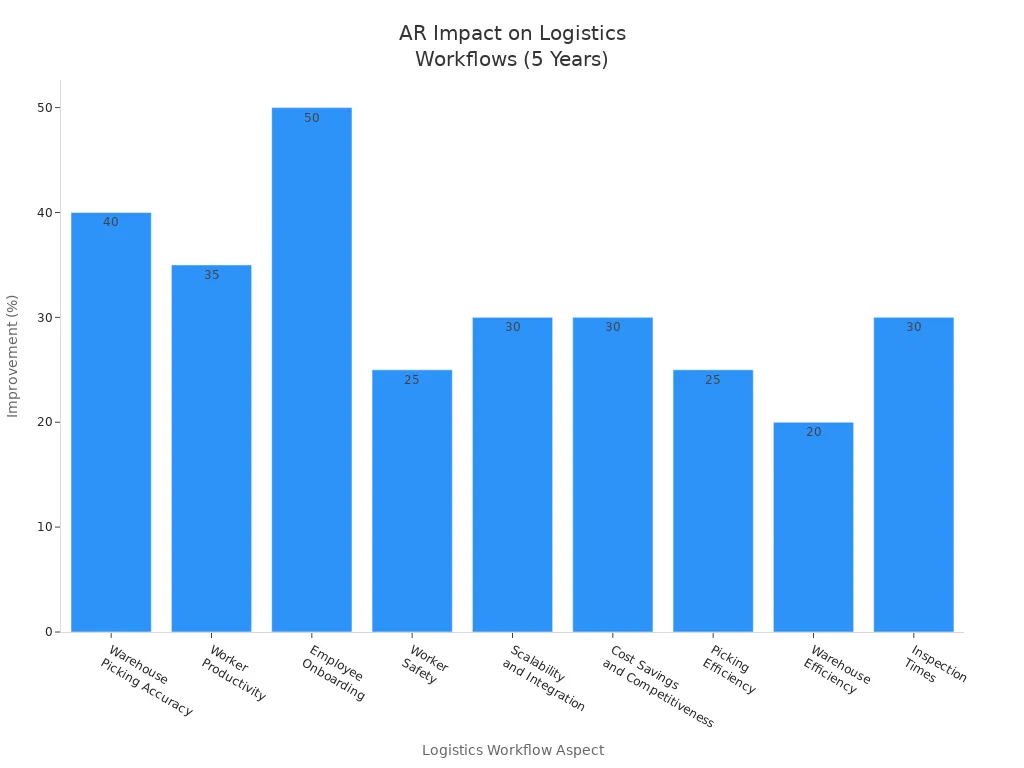

Augmented reality and immersive tech will change logistics soon. Smart glasses with AR help workers see what to pick and show data right away. These tools help workers make fewer mistakes. Companies using AR say they get over 99% picking accuracy and 40% fewer errors. Workers finish jobs 35% faster when they use AR for training. AR alerts warn workers about dangers, so there are 25% fewer injuries.

Aspect of Logistics Workflow | Impact of AR and Immersive Technologies | Supporting Data / Outcome | Company Example |

|---|---|---|---|

Warehouse Picking Accuracy | Increased accuracy and reduced errors | Over 99% accuracy; 40% fewer picking errors | General (Accenture 2023) |

Worker Productivity | Increased speed and reduced errors | 35% faster task completion with AR training | PwC Workforce Research |

Employee Onboarding | Reduced onboarding time and turnover | 50% reduction in onboarding time; 25% higher job satisfaction | Deloitte Logistics Report |

Worker Safety | Enhanced safety through real-time alerts | 25% reduction in workplace injuries | General AR overlays |

Scalability and Integration | Improved system scalability and flexibility | 30% increase in scalability; seamless integration with WMS/ERP | Capgemini Research Institute |

Cost Savings and Competitiveness | Reduced operating expenses and increased agility | 30% cost savings over five years | Gartner Analysis |

Picking Efficiency | Increased order selection efficiency | 25% improvement in picking efficiency; reduced errors | DHL |

Warehouse Efficiency | Improved warehousing operations and inventory accuracy | 20% efficiency increase; 30% fewer stock inconsistencies | XPO Logistics |

Inspection Times | Reduced inspection and bottleneck times | 30% reduction in inspection times; fewer supply chain interruptions | BMW |

Training

Training for logistics workers is getting easier with wearables. Smart devices link to warehouse systems and give simple steps to follow. New workers learn faster and make fewer mistakes. Self-learning tools help workers get good at their jobs quickly. Exosuits and other gear need to fit right and need training. Ongoing help and clear lessons about the benefits make workers like new tech more. Good change management helps everyone use new tools well.

Tip: Companies that spend money on training and support have happier workers and faster training.

Industry Evolution

Wearable technology will keep changing logistics jobs. AI-powered wearables watch worker health and stress to keep them safe and working well. Devices like smart gloves and helmets collect data and give feedback right away.

When these connect with IoT and AI, work gets faster and smarter. Companies can see and control their supply chains better. There are still problems like battery life and privacy, but new ideas will help. Connected workplaces help teams talk and finish jobs faster, so they can handle new business needs.

Recent stories show that smart devices help logistics companies a lot. They make work safer and help people do more. They also help managers make better choices.

FM Logistic made dangerous moves happen 30% less in half a year.

Some companies spend up to 20% less money and help customers 30% better.

Logistics leaders can do these things to do well:

Make simple plans for using new devices.

Pick tools that match what the company needs.

Teach workers well and check how things are going.

The logistics field will keep changing as new technology makes work safer, quicker, and smarter.

FAQ

What is wearable technology in logistics?

Wearable technology means workers wear smart glasses, scanners, or sensors. These devices help workers find and move goods. They also help workers do their jobs better and safer. Companies use them to make warehouse work faster and more correct.

How do wearables improve worker safety?

Wearables watch how workers move and check their health. They warn workers and bosses if something is not safe. They also warn if someone is too tired. This helps stop injuries and keeps everyone safe at work.

Are wearable devices hard to use?

Most wearable devices have easy screens and voice controls. Workers can learn to use them fast. Companies give training and help so everyone feels good using the new tools.

What data do wearables collect?

Wearables collect things like where workers are and what jobs they do. Sometimes they collect health details too. Bosses use this data to make work safer and better. Companies must keep this data safe and follow privacy rules.

Can small logistics companies afford wearable technology?

Wearable technology can cost a lot at first. Some companies buy a few devices and add more later. Renting devices or getting grants can help small businesses pay for them.

How does wearable technology improve warehouse productivity?

Wearable barcode scanners and computers help workers perform tasks faster by freeing up their hands. This reduces scanning time, improves picking accuracy, and minimizes errors, all of which contribute to higher productivity.

What is the role of wearable devices in transportation and logistics?

Wearables provide real-time tracking, scanning, and communication tools for delivery drivers and warehouse staff. They ensure smoother coordination across the supply chain and reduce manual paperwork, making transportation and logistics more efficient.

Why is real-time data important in logistics operations?

Real-time data allows logistics teams to track inventory, shipments, and employee performance instantly. It helps prevent delays, improves decision-making, streamline operations and ensures better customer service through accurate delivery updates.

How does wearable tech enable real-time information access?

Devices like wearable computers and smart scanners sync with cloud-based systems, providing workers with up-to-date instructions, inventory data, and order information directly on their wearable screens or mobile apps.